At the purchase, two flasks were welded under the chassis in order

to allow the bolting of a support to hang the exhaust pipe.

Such support was not present at the purchase.

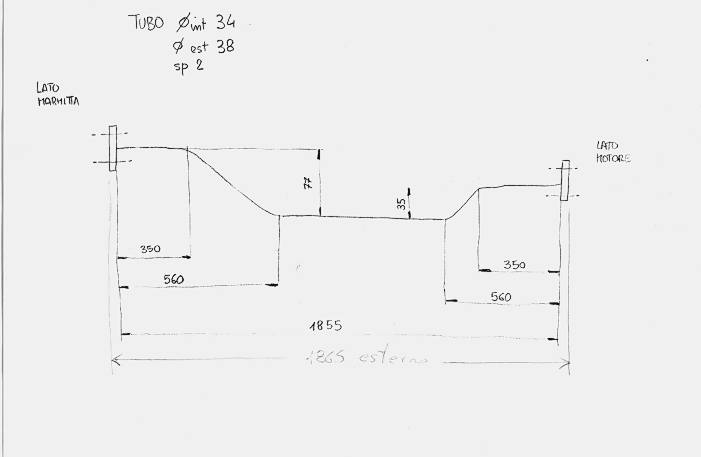

The flasks are welded not in line with the existing exhaust (see picture herebelow) that

runs straight from the outlet flange of the manifold to the inlet flange of the silencer.

Such off-set (35 mm) could be understandable only if, originally, the chassis was designed

for the “preserie” models having the exhaust with vertical silencer placed

beside the engine ( in this regard the chassis of the 7A 001030 has a passage (closed by a

small steel cover) on the left side of the engine in order to allow the the passage of the

vertical silencer).

In such case the exhaust pipe of the 7A “preserie” type would be in line with

the flasks.

|

Technical considerations

At the purchase, the exhaust support was missed and the exhaust pipe was

directly fixed to the engine manifold on one side and fixed to the silencer on the other

side.

By the provision of a central support the exhaust is well tightened but no more

flexibility between the central support and the engine manifold exists.

The consequence is that any possible movement of the engine is adsorbed by the manifold.

Since the manifold is breakable, not available as spare, not easy to refabricate, it is

decided to insert an expanding joint, the same type provided on the subsequent type 7C

(lenght 300 mm).

The original asset of the 7A in this case is not applied but the risk to break the

manifold is avoided.

|